'The System'

Traditional and contemporary insights about System, Process and Improvement trends and experiences.

Audit Planning

How do you plan your organisational or project process audits?

How do you plan your organisation’s or project's process audits?

Are you still relying on:

- your memory’s total recall?

- retained hand marked up shop floor/field/site working notes?

- laboriously retrieving previous report files from your disorganised email sent folders?

- cumbersome action list registers tracking actions close-out?

- manually cutting/pasting standard audit questions only covering ISO standards and not your own processes?

- searching through multiple (company and employee) shared cloud drives and not finding the reports/templates you're looking for because the navigation is so complicated! and the search feature never works!

- scouring for printed hard copies reports in shoe boxes kept under the manager's desk (not kidding, I've seen it!).

- last minute scrambling to “close out” (including 3rd party certifier) raised issues before you start - to check “effectiveness” during- your audit?

Do you actually do any preparation?..For every audit, you use the same excel template, print it and go and ‘jot’ down one or two samples to verify compliance and absolutely never raise a finding! Now is that an effective use of resources? (a part time ‘QA person’ doing this job didn’t think so either and left the company!) Who would want to be given such a job?

Are you accepting 3rd party auditor raised issues without question..without their own full understanding of how your systems and processes function? If yes, any subsequent corrective actions will only result in “tampering”, destroying your systems and processes!

Have your external auditors clearly understood their objectives?

Do Company and Project Leaders:

- have confidence in and real understanding of operational and administration process compliance levels?

- still accept tick-and-flick work just to be satisfied something is being done?

- or, is their mind set constantly on systems and process improvement and removing variation?

Improve:

Step back and think through about the audit purpose? Is it just about process compliance, or is there more to it?

If you have a defined, standard process to assure process consistency, look at it.. Is it still relevant? Work through it with the process owners.

Examine historical reports and findings for any raised or suggested actions. Did any actions help improve anything or did they make the system worse?

How about the inspections, (internal checks - for the benefit of the ‘next’ customer in the process) 'inside' critical processes providing real time knowledge of variation levels and process stability/predictability? Does the measure show improvement? Have there been concerted efforts to trigger an improvement with clear understanding between common and special causes? Is the data trending toward process warning limits to soon require process adjustment?

A simple plot of (sampled) data points over time, may be enough.

Audits are an ideal time to discover any process barriers, possibly impeding on process output, uniformity and quality. The causes may be in the work environment, work methods, supplied materials, machine settings, maintenance, all hindering process performance.

The era of tick-and-flick compliance and disorganised audit preparation must end.

If just checking for “assurance” and verifying the “fire has been put out” you are still back where you were!

The audit process must aim to add benefits beyond your systems and processes...to the customer’s (customer’s) customer!

Unique and powerful methods to streamline your systems and processes.

We provide customised client specific business solutions and coaching for you to:

- Envision Systems

- Enable Processes and

- Enhance improvement

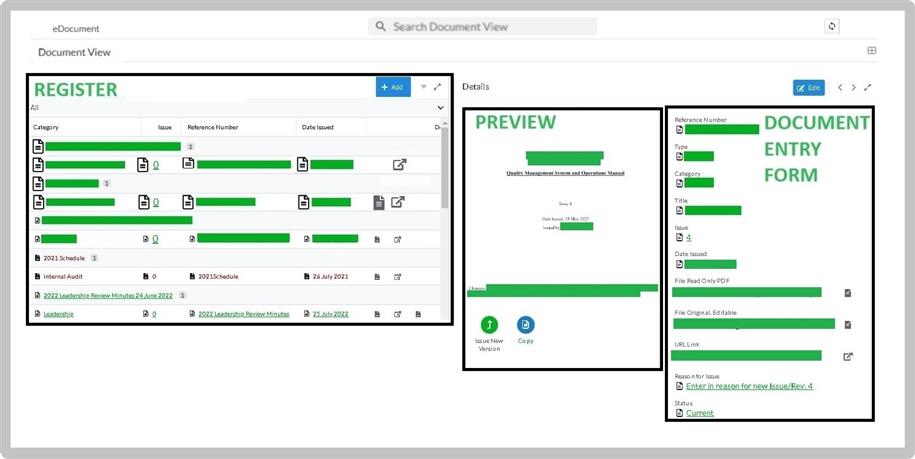

eDocument

Central Enterprise Project Document Control System

- Local Enterprise Server Data Hosting

- Google Cloud App

- Work teams setup

- Access/read-only security

- Traceable review comments

- One click up-revs & automated superseding

- In-app auto email team/review approval/

workflow

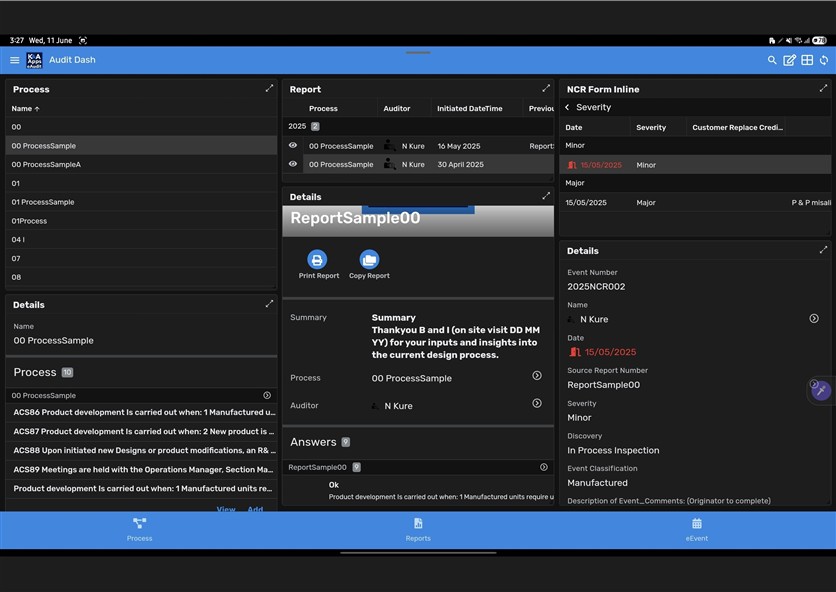

eAudit

On line eAudit System Application

- On-line Audits & Inspections

- ISO Leadership Standard compliance (9001, 27001, 14001)

- Preset or custom compliance questions

- Objective evidence photos, file upload, url

links

- Remote site local device data storage

- PDF reports

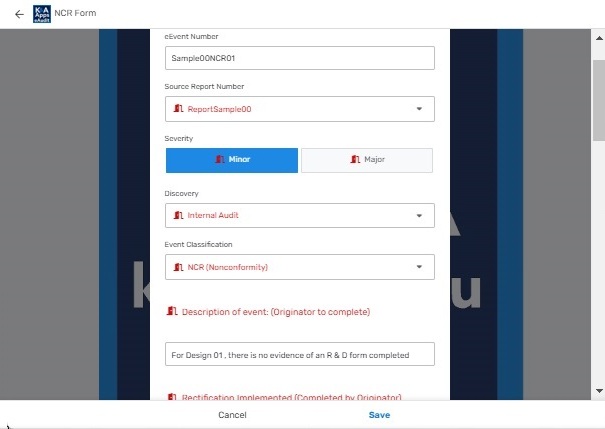

eEventNCR

Define, investigate, resolve & prevent undesired events

- Track/Resolve incidents, nonconformity, eAudit findings

- Severity based investigation detail

- Investigation and close out team authorisation

- Customised fields and work flow

- Reporting views

- PDF reports

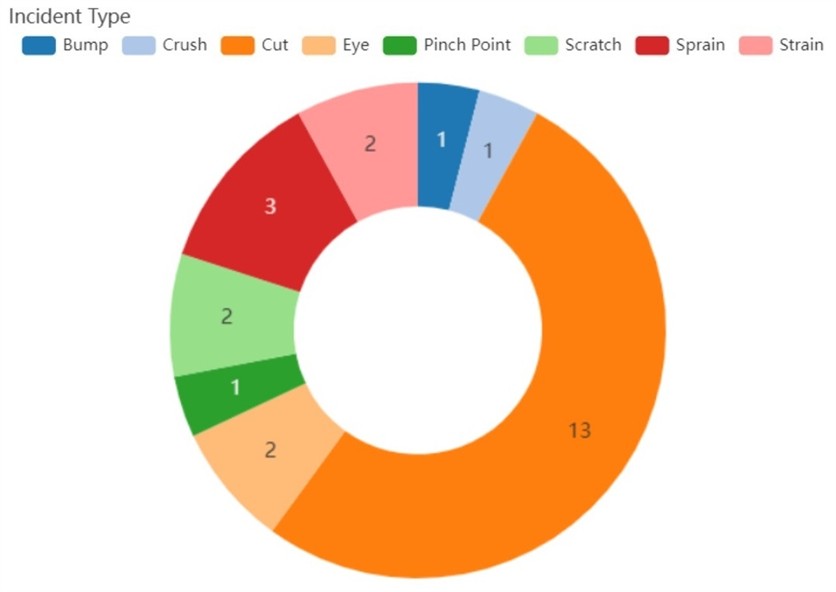

eSafe

Track, Chart incidents by type, machine, location

- Immediate incident evidence:

- - photos

- - eye-witness accounts

- ISO 45001 compliant

- Location reporting:

- - GMap (lat long)

- - Detailed site/build plan

- Stratify data/metrics for effective analysis

- Record/track all workcover incidents & metrics

"If everybody did their best, 95 percent of problems would remain" W. Edwards Deming

Thank you and regards,

Nik